Abstract

This article is the second and concluding part of a two-part series on sustainable ship recycling which is the outcome of a project on “Sustainable Ship Recycling in India” being undertaken by a National Maritime Foundation (NMF) team comprising Commodore Debesh Lahiri, Executive Director, Rhythma Kaul, Associate Fellow; and Ayushi Srivastava, Research Associate. Since, this research article is an outcome of Corporate Social Responsibility (CSR) funds from the Goa Shipyard Limited, a deliberate attempt has been made by the authors to educate the lay public about the basics of sustainable ship recycling. Ship recycling — in the earlier times referred to as ship breaking — deemed the most environmentally friendly and economically viable method for final disposal of End-of-Life (EOL) vessels, witnessed a historical shift from Europe and the United States to the developing world with more lenient regulations post-1970s. This relocation, driven by stricter social and environmental laws in the Global North, raised concerns about safety standards in ship recycling yards in the Global South. Managing EOL marine structures necessitates sustainable practices due to potential environmental and health hazards. This article focuses on the social, technological and environmental aspects of enhanced recycling, reusing, and disposal techniques, outlining their contributions to the marine industry’s long-term sustainability. Specifically, it sheds light on India’s Alang-Sosiya Ship Recycling Yard (ASSRY). The authors, informed by stakeholder interactions and on-site visits, propose short-, medium-, and long-term measures for the Indian ship recycling industry, aiming to elevate sustainability standards and position India as a leader in ship recycling with heightened sustainability criteria.

Keywords: Alang-Sosiya Ship Recycling Yard, Ship Breaking, Ship Recycling, Hazardous Waste, Gujarat Maritime Board, Maritime India Vision 2030, Maritime Amrit Kaal Vision 2047, Hong Kong Convention, European Union Ship Recycling Rules, Workers Training and Safety, Sustainability, Carbon Emission, Green Ship Recycling

Navigating the Seas of Ship Disposal

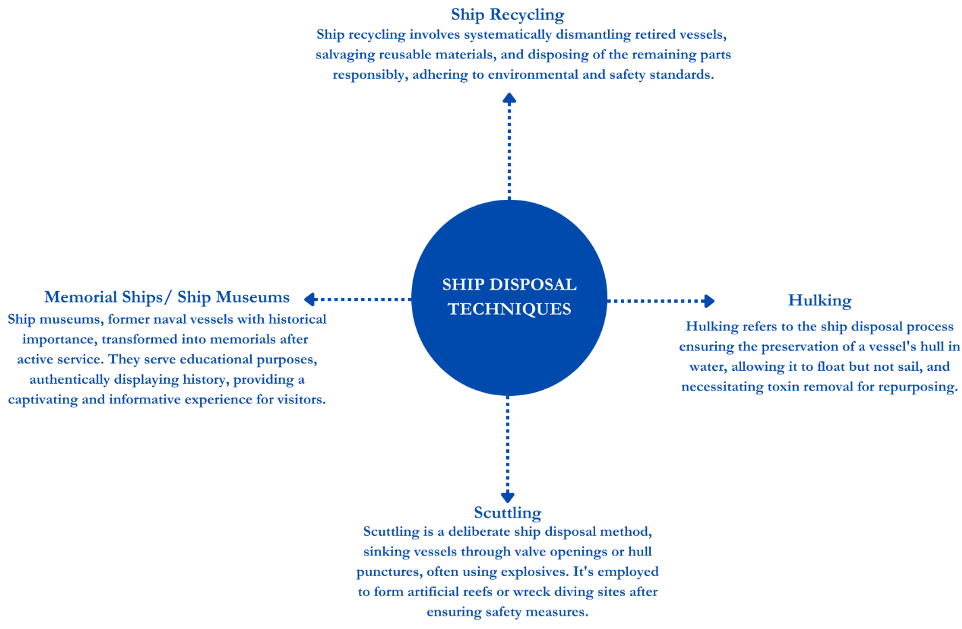

In the intricate tapestry of global trade, the shipping industry emerges as a vital component, facilitating the movement of goods across seas that form the arteries of our interconnected world.[1] With ships typically boasting a lifespan of 25-30 years, the question of their disposal becomes a critical decision point where economic considerations need to be balanced vis-a-vis environmental responsibility.[2] Post their operational life, a significant number of vessels find their way to ship-breaking yards, transforming into inventories of steel, iron, and other valuable resources. The challenge of environmentally safe disposal of EOL ships becomes particularly pronounced in a globalized world, where the world trade fleet assumes a pivotal role in curbing transport costs.[3] Addressing the issue of EOL vessels demands responsible disposal methods, where scuttling of vessels in the open oceans should be the last resort.[4] The array of alternative options available encompasses vessel reuse or land-based recycling or repurposing for use as an artificial reef.[5] The principles established by the United States Environmental Protection Agency’s Marine Protection, Research, and Sanctuaries Act (US EPA-MPRSA) can serve as a guiding framework in navigating these choices.[6] The above act reinforces the importance of prioritizing a balanced and sustainable approach, with a particular emphasis on land-based disposal methods such as ship recycling. The MPRSA underscores the significance of ecosystem preservation during ship disposal, marking a notable shift towards a heightened awareness of responsible practices that aim to shield marine environments from potential adverse effects.[7]

Figure 1. Common Ship Disposal Techniques

Source: Collated by the authors

While the ship breaking industry was predominantly concentrated in Europe and the United States before the 1970s, a notable shift occurred thereafter as it migrated to regions with more lenient legal frameworks.[8] This transition was spurred by the imposition of stricter social and environmental protection laws in the Global North, raising concerns about the standards being followed in ship recycling yards.[9] Currently, South Asia has emerged as the epicentre for the ship-breaking industry, with Bangladesh, India, and Pakistan garnering an overwhelming majority of ship recycling orders.[10] Despite initial apprehensions about environmental damage, there is a glimmer of optimism in recognizing ship recycling as the optimal way to retire vessels.[11] This approach involves repurposing and recycling approximately 90% of the materials, presenting an efficient method that not only saves resources but also aligns with sustainable practices.[12] As surprising as it may seem, the ship-breaking industry, often viewed with scepticism, holds the potential to transform into an environmentally friendly enterprise.[13] A case in point is Alang in Gujarat, India, where a transition towards sustainable ship recycling practices is underway, showcasing the possibility of converting what was once a serious environmental concern into a beacon of environmental responsibility.

The International Maritime Organization (IMO) has also played a pivotal role in addressing ship recycling concerns since the 44th Marine Environmental Protection Committee (MEPC) session in 2000. Initiated by a correspondence group, the IMO developed Guidelines on Ship Recycling, and adopted it in 2003, advising stakeholders worldwide. Recognizing the urgency of incorporating environmentally friendly guidelines in ship recycling the MEPC 53 in 2005 prioritized a legally binding instrument on ship recycling, emphasizing safety, environmental sustainability, and an enforcement mechanism. This led to the development of the Hong Kong Convention (HKC), adopted in 2009 after collaborative efforts. The convention signifies IMO’s commitment to minimizing environmental and safety risks, ensuring sustainable ship recycling practices, and addressing the unique challenges of the world maritime transport system.[14] The HKC enters into force on June 26, 2025.[15]

India’s Dynamic Ship Recycling Landscape

India stands as the world’s second-largest player in the ship recycling industry, only behind Bangladesh.[16] The focal point of India’s ship recycling prowess is the ASSRY in Gujarat, a coastal stretch in the Bhavnagar district spanning more than 10 kilometres.[17] Alang commands a staggering 98% of India’s ship recycling capacity and significantly contributes 32.6% to the global recycling volume.[18] However, despite its abundant potential, the current state of affairs at Alang reveals a surprising statistic — 48% of its existing ship-breaking capacity remains idle.[19]

The ASSRY consists of 153 plots, with 131 plots currently being utilised for shipbreaking activities with the balance 22 plots in disuse pending litigation. However, only 80 of these 131 plots are presently operational, hinting at an untapped potential waiting to be harnessed. This under-utilization contrasts with the industry’s peak year in 2011-12 when 415 ships, totalling 3.85 million Light Displacement Tonnage (LDT), flocked to Alang. This period was the zenith, with shipbreaking activities almost reaching the full capacity of 4.5 million LDT. Subsequently a decline ensued, exemplified by the fiscal year 2019-2020, witnessing only 202 ships with 1.62 million LDT. The fiscal year 2020-2021, until January 2021, showed a modest improvement with 199 ships and 1.8 million LDT.[20]

Figure 2. Google Earth View of Alang Sosiya Ship Recycling Yard Source: Google Earth[21]

In a bid to fortify its position in the global ship recycling landscape, India has ambitious plans to augment its recycling capacity up to 9 million LDT.[22] The industry currently provides gainful employment to a substantial workforce of 5.15 lakh people. Notably, over the last five years, the ship recycling sector has contributed an average revenue of ₹ 55 Crores per annum, emphasising its economic significance and sustained growth potential.[23] The ship recycling activities in India are also conducted in a limited manner at the Kidderpore Docks, Syama Prasad Mookerjee Port, Kolkata; the Mumbai Port, and by the Steel Industrials Kerala Limited.[24]

The ship recycling sector at Alang is emerging as a pivotal player, skilfully navigating the delicate balance between economic advancement and environmental sustainability. Alang’s significance extends beyond its contribution to the global ship recycling industry; it plays a crucial role in generating approximately 3.50 million Metric Tonnes (MMT) of steel annually, producing substantial quantities of re-rollable steel without depleting natural resources or triggering the environmental impacts associated with traditional steel production processes, such as mining, energy consumption, water usage, and toxic effluents. The potential to produce re-rolled steel positions Alang as a green route for generating secondary steel, offering a sustainable alternative to extracting steel from Iron ore. A comparison between the resource requirements for producing 4 million tonnes (Mt) of steel through the conventional route and ship recycling route is illustrated in the accompanying Table 1 to drive home the environmental advantages and sustainability inherent in Alang’s ship recycling practices.

| Sl No | Natural Resources | Steel Plant | Ship Recycling Industry | Saving in Ship Recycling |

| 1 | Iron Ore (t) | 7,000,000 | 0 | 7,000,000 |

| 2 | Refractory materials / additives (t) | 2,800,000 | 0 | 2,800,000 |

| 3 | Coal (t) | 6,200,000 | 0 | 6,200,000 |

| 4 | Process Chemicals (t) | 160,000 | 0 | 160,000 |

| 5 | Oxygen (Nm3) | 260 x 106 | 72 x 106 | 188 x 106 |

| 6 | Water (Million m3) | 100 – 240 | 0.80 | 99.2 – 239.2 |

| 7 | Fuel Oil (t) | 120,000 | 220,000 | -100,000 |

| 8 | LPG (t) | 0 | 16,000 | -16,000 |

| 9 | Energy (as fuel and electricity) (J) | 80,000 x 1012* | 80,000 x 1012 | 0 |

| t – tonnes

Nm3 – Normal cubic meters. The ‘Normal’ refers to normal conditions of 0 degrees Celsius and 1 atm (standard atmosphere = 101.325 kPa) – for particle purposes this is rounded to 1 bar J – Joules * Does not include energy required for transport of raw materials to plant site |

||||

Table 1. Resource Requirements for Producing 4 Mt Steel by Conventional Route and by Ship Recycling Route Source: Environmental Impact Assessment and Environmental Management Plan[25]

According to the Gujarat Maritime Board, a comparison of natural resource consumption in the production of 2 million tonnes of steel through a steel plant and ship recycling reveals significant savings in the latter in two key aspects. Firstly, in terms of solid waste, the steel plant generates approximately 878,967 tonnes, while the ship recycling industry produces only 12,500 tonnes, resulting in a substantial total saving of 866,467 tonnes of solid waste or a savings of 433234 tonnes of solid waste per tonne of steel produced. Secondly, the steel plant incurs a total cost exceeding ₹1000 crore, whereas the ship recycling industry’s total expenses are less than ₹100 crore, culminating in an overall saving of around ₹ 900 crore or a saving of ₹450 crores per tonne of steel produced.[26]

Additionally, Alang Sosiya Ship Recycling Yard (ASSRY), with an existing ship recycling capacity of about 4.5 million tonnes per annum, has the potential to reduce annual CO2 emissions by 7.34 million tonnes compared to conventional steel production from iron ore.[27] It is therefore evident that responsible ship recycling is a sustainable route towards India becoming more environmentally conscious and contributing to the reduction of greenhouse gas emissions, in alignment with India’s net-zero emissions target by 2070.[28] With more than 100 recycling plots adhering to the Hong Kong Convention standards, Alang stands as a beacon of environmentally responsible ship recycling.[29]

While there are numerous advantages in undertaking ship recycling in India, the country must address significant challenges within the Indian Ship Recycling Sector. These challenges, extensively discussed in the first segment of this two-part series on sustainable ship recycling — an outcome of the “Sustainable Ship Recycling in India” project by Team NMF — are diverse and complex, impacting the sector’s overall operation and growth trajectory.[30] A key challenge involves the industry grappling with enhanced legal and administrative costs incurred to comply with Health, Safety, and Environment (HSE) regulations.[31] The necessity to meet rigorous regulatory standards requires substantial investments to ensure worker safety and environmental protection, thereby adding a considerable financial burden to the sector. Consequently, there is a pressing need for comprehensive policy reforms, strategic planning, and collaborative efforts to address regulatory, operational, and financial constraints collectively. Successfully overcoming these obstacles is crucial for the Indian ship recycling sector to thrive, contribute sustainably to the economy, and establish itself as a global player in the ship recycling industry.

Alang: India’s hub for ship recycling

Alang, having evolved into the central hub for shipbreaking activities now known as recycling, is a testament to India’s dedication to maritime endeavours and environmentally responsible practices. The Gujarat Maritime Board (GMB) after a thorough survey of the coastal region, ultimately designated Alang as the most suitable site for developing shipbreaking operations.[32] Both the GMB and other interested stakeholders endorsed this selection based on key factors highlighted in the first part of this two-part article.

The site’s strategic positioning within the high tide zone and ideal weather conditions supports continuous ship breaking operations. Additionally, Alang boasts other favourable conditions viz., the seabed’s quick drying capability, even during monsoons, which facilitates the handling of various materials and equipment involved in the ship breaking process; the sloping coast of Alang, along with a long dry area, facilitates the uninterrupted beaching of vessels, thereby enhancing the overall handling of end-of-life (EOL) vessels. Moreover, the coastal area of Alang is strategically devoid of other competitive users, such as merchant shipping, fishing, and salt pans.[33] This unique combination of geographic advantages has catapulted the Alang-Sosiya Ship Recycling Yard (ASSRY) as a major player in the ship recycling industry. It not only highlights India’s commitment to sustainable maritime practices but also emphasizes the crucial role ASSRY plays in fulfilling the escalating demand for steel while adhering to responsible environmental practices. In essence, ASSRY emerges as an invaluable asset for India’s ship recycling industry.[34]

Figure 3. Bhavnagar anchorage area

Source: Captured by authors during the visit

Upon entering the Indian Maritime Zone for ship recycling, vessels must notify both the Maritime Rescue Co-ordination Centre (MRCC) and the Indian Coast Guard regarding their intended destination at ASSRY. Subsequently, the vessel seeks permission to drop anchor, a step facilitated following a thorough desk review conducted by the Port Authority, Gujarat Maritime Board (GMB), and Customs.[35] The detailed process is already explained in the first part of the duology under the heading “Ship Recycling Step-by-Step Procedure.” The comprehensive ship recycling cycle, spanning inspection, preparation, and certification, ultimately culminates in the recycling of the ship’s steel and other reusable products.[36]

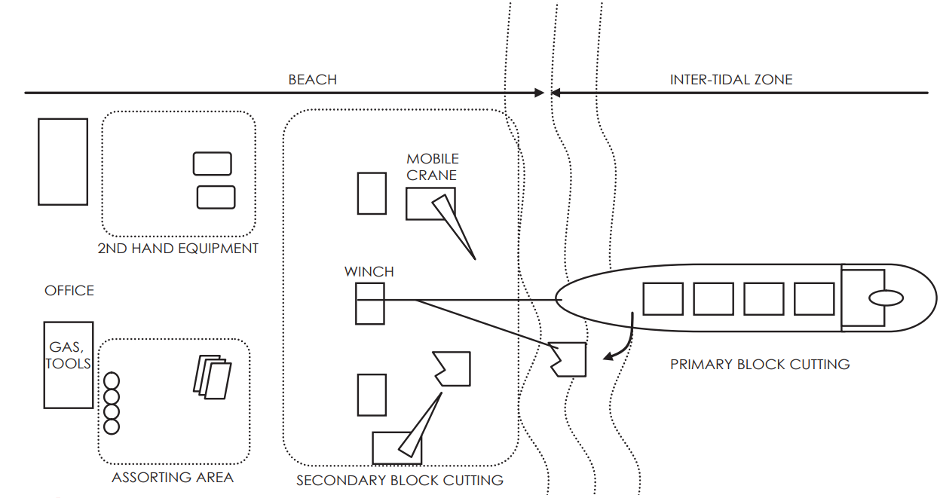

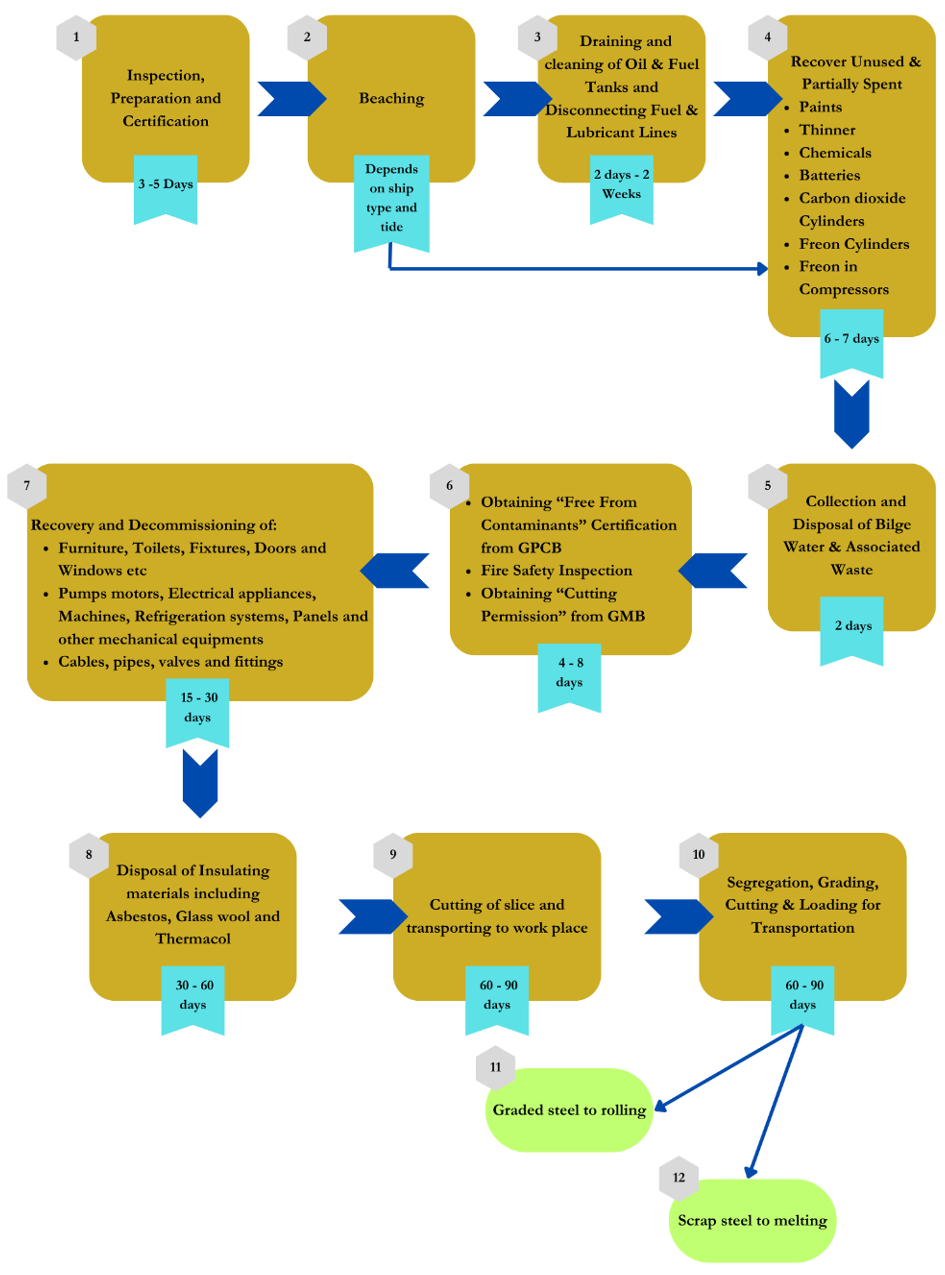

Once a vessel enters a ship recycling yard, it undergoes a planned series of steps, starting with the critical process of beaching. During this phase, the ship is intentionally grounded in shallow water, rendering it immobile and irreversible.[37] A typical beaching scenario in Alang is illustrated in Figure 4.

Figure 4. Typical Beaching in Alang

Source: Arya Steel Handbook[38]

The duration for entire ship recycling process varies, ranging from 3.5 to 9 months, contingent upon factors such as the vessel’s size and type. Despite the specific recycling plans and procedures of each yard, a common and time-tested tacit know-how prevails in Alang, as depicted in Figure 5, illustrating the “typical ship recycling procedure.” This standardized approach ensures economic, procedural, environmental, and work-safety advantages, with each work activity’s duration and input-output meticulously outlined for efficient execution.

Figure 5. Typical Ship Recycling Procedure

Figure 5. Typical Ship Recycling Procedure

Source: Collated by Authors

The representatives of the European Union and the media continue to highlight serious concerns in ASSRY with respect to pollution in the intertidal area; the absence of medical facilities; breaches of labour rights; and challenges in managing hazardous waste streams including mercury and radioactive contaminated materials commonly found in offshore oil and gas units. The resale of asbestos-contaminated materials in India and the absence of a proper disposal site for PCBs further contribute to the negative perception of Alang-Sosiya.[39] However, a closer examination of the ASSRY reveals noteworthy progress compared to the previous decade. Out of the total 153 plots, approximately 103 are procedurally compliant with the Hong Kong Convention (HKC), and about 27 yards are actively striving for compliance with the European Union Ship Recycling Regulations (EUSRR). Recent efforts by the authorities has resulted in a more positive impact on the safety and well-being of workers and the environment, showcasing a commitment towards addressing the previously identified concerns. These ongoing efforts are indicative of a proactive approach to enhance sustainability and compliance within the ship recycling industry in Alang.

SOCIAL PERSPECTIVE

Workers Training and Safety

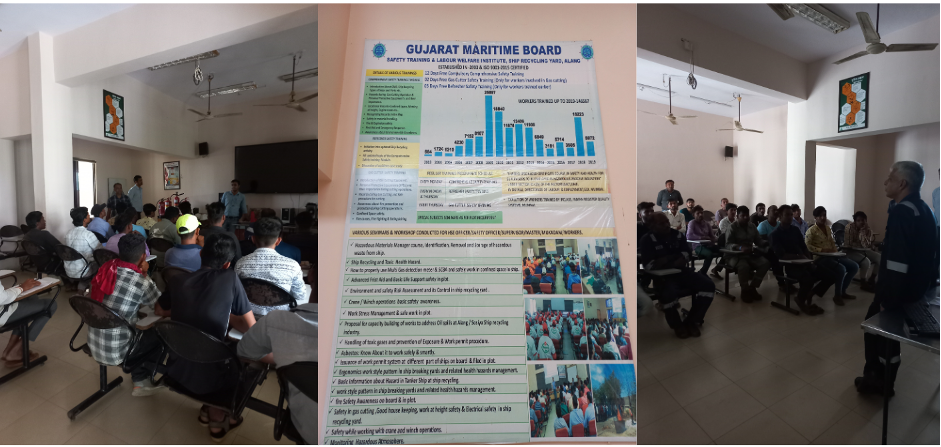

Figure 6. Safety Training and Labour Welfare Institute

Figure 6. Safety Training and Labour Welfare Institute

Source: Pictures taken during the interaction of Team NMF with the trainees at the institute.

Amidst concerns raised by organisations regarding worker safety and training in Alang, interactions with the workers at the Safety Training and Labour Welfare Institute reveals a starkly contrasting reality. The institute, operating in Alang, has demonstrated significant success in reducing accidents through its rigorous training programs. Notably, the reported fatalities resulting from yard accidents have been limited to eleven between 2020 and 2023, showcasing the tangible impact of safety initiatives. The comprehensive approach to safety is amply evident in the assignment of a dedicated Safety Officer to each recycling plot, supported by one or more safety supervisors. Moreover, the office of the Gujarat Maritime Board (GMB) at Bhavnagar has a Safety Department staffed with qualified Safety Officers, emphasizing a systemic approach towards ensuring worker safety.

|

Accident Data |

|||||||||||||

| Year | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 |

| No. of Fatal | 5 | 15 | 9 | 18 | 4 | 7 | 8 | 12 | 1 | 0 | 2 | 8 | 1 |

Table 2. Accident Data of ASSRY

Source: Data provided by ASSRY Authorities

Since its establishment in 2003, the Safety Training and Labour Welfare Institute has enjoyed the unwavering support of the Gujarat Maritime Board, resulting in the proficient training of 1,56,503 skilled professionals. The training program, comprising mandatory 12-day comprehensive safety training, an intensive 2-day gas cutter safety training customized for gas cutting activities, and a comprehensive 3-day refresher safety training for personnel with prior training, underscores a commitment to empowering workers with the necessary skill-sets for their tasks. Additionally, the institute conducts seminars at regular periodicities addressing pertinent subjects to meet the distinct requirements of individual yards.

In line with their commitment towards welfare of workers, Alang authorities have constructed seven residential blocks, providing well-designed accommodations for a total of 1008 workers. These initiatives reflect a proactive stance towards enhancing the comfort and safety of workers, challenging the negative perception propagated by external vested entities. The water supply to ASSRY is facilitated through a pipeline connected to the Gujarat Water Supply Board. The capacity of the clean water supply system is 3 million litres per day, which comfortably exceeds the daily requirement ranging from 1.6 to 1.8 million litres. As a result, there is generally no issue with water supply. However, occasional shortages may arise during the summer months. In such cases, additional fresh water is supplied through tankers to ensure that the balance requirement is adequately met.[40]

Figure 7. Multi-specialty hospital and Accommodation Block

Source: Pictures taken during the visit of Team NMF to Accommodation block and multi-specialty hospital

Medical Facilities

Significant strides have been made in improving the medical facilities in Alang, addressing concerns and enhancing the overall well-being of the workforce. Presently, three medical facilities operate in the area — a multi-specialty hospital, a primary hospital, and a mobile health unit — all managed jointly by the Indian Red Cross Society and the Gujarat Maritime Board. These facilities are equipped to handle routine medical care, attend to minor injuries, perform surgeries, and provide immediate relief in the event of significant accidents. The expenses associated with medical treatment are covered by the plot owner where the injured worker was employed, emphasizing a collaborative approach to worker health. Complementing these efforts, the Ship Recycling Industries Association (SRIA) is at an advanced stage of establishing a Trauma Centre, Health Care Centre, and Welfare Centre dedicated to Alang’s workforce. Furthermore, the Gujarat Maritime Board is converting a building owned by the Justice Dewan Charitable Trust into a comprehensive hospital specifically catering to ASSRY workers, with SRIA covering all associated costs. To promote occupational health awareness, the GMB’s Training Centre, SRIA’s medical professionals, along with external experts, conduct informative campaigns, demonstrating a holistic commitment to improving and expanding medical facilities in Alang.

TECHNOLOGICAL PERSPECTIVE

Figure 8. Geo-membrane layer on the yard and Liquid Oxygen supply tank in a yard

Figure 8. Geo-membrane layer on the yard and Liquid Oxygen supply tank in a yard

Source: Pictures taken during the visit of Team NMF to ship recycling yards

Alang has made significant strides in improving its ship recycling infrastructure and technology, introducing innovative measures to enhance safety and environmental sustainability within the ship recycling industry. The integration of liquid oxygen in the yards has streamlined gas cutting processes, providing a more efficient and controlled approach. Moreover, the strategic plans to transition towards plasma and water-jet cutting technologies in the coming years stresses the industry’s commitment towards embracing advanced environment-friendly technological capabilities. Another noteworthy development is the incorporation of geo-membrane layers in a majority of the yards. Comprising impermeable geosynthetic material, these layers act as a robust barrier, preventing the seepage of harmful contaminants and hazardous chemicals into the soil. This proactive measure not only safeguards the soil from potential hazards but also demonstrates a conscientious effort to mitigate environmental impact.

ENVIRONMENTAL PERSPECTIVE

In the pursuit of sustainable ship recycling, Mecon Limited conducted a comprehensive environmental assessment survey focusing on air and water quality, noise levels, and ecological impact in the Alang region. The ambient air quality at five distinct locations, including Alang village and Sosiya village, was diligently monitored for Particulate Matter (PM10 and PM2.5), Sulphur dioxide (SO2), and Oxides of Nitrogen (NOx). The results of the survey spanning a twelve-week period, revealed that the ambient air quality parameters in the villages adhered to the National Ambient Air Quality Standards, 2009 for “Industrial, Residential, Rural, and Other Areas.” Work zone air quality within ship breaking plots and the Alang Waste Treatment Storage Disposal Facility (TSDF) met the stipulated norms outlined by the Indian Factories Act.[41] Water quality monitoring covered sea water, Pasvivali Creek, ground water, and effluents from ships and the Alang TSDF. Sea and creek water analysis indicated levels within limits stipulated in the “Primary Water Quality Criteria for Coastal Waters,” while ground water from Alang and Mathavda villages was deemed unsuitable for drinking. In terms of noise pollution, continuous monitoring at Alang Fire Station and surrounding villages demonstrated that average noise levels met the standards for Residential and Industrial Areas prescribed by the Central Pollution Control Board.[42]

The ecological study revealed a semi-arid landscape with sparse vegetation dominated by Prosopis juliflora (Gando-baval) and a limited variety of land animals. In addition to the absence of ecologically sensitive areas and mangroves, the study identified presence of common bird species but reported low biodiversity and biomass of marine life in the Alang area, with no commercial fishing activities.[43] Overall, this comprehensive environmental analysis, conducted by Mecon Limited and observed by the authors through engagement with stakeholders and authorities, forms a crucial foundation for ensuring responsible and sustainable ship recycling practices in the region.

Method of Identification, Removal and Disposal of Hazardous Inventory

- Asbestos is normally found in insulation areas like bulk head, pipe insulation, cold or hot areas needing insulation in machinery and engine room spaces. Ceilings are also often found containing asbestos in ships. Removal of asbestos is done in a negative pressure area wherever required. Special signage is used on vessels and on bags during compilation of the Inventory of Hazardous Material (IHM) for identification of items containing asbestos on ship. Green Gene Enviro Protection and Infrastructure Private Limited (GGEPIL) approved by the Gujarat Pollution Control Board (GPCB) is contractually authorised to handle, transport and dispose materials in accordance with laid down regulations from hazardous material storage to GGEPIL’s processing plant. It bears mention that the quantum of asbestos being used on ships is constantly decreasing and most ship designs are aiming to be asbestos-free.

- Paints used on vessels in 70s and 80s used to contain asbestos and Tributyltin (TBT). In case, scrutiny of the IHM or available vessel data reveals that the paints used onboard the vessel contain any of the hazardous ingredients, then the paint chips are removed with utmost care by chipping method. Special signage is used on vessel for bags containing paint chips which is sent to the Treatment, Storage and Disposal Facility (TSDF) / GGEPIL in Alang.

- Oily Sand and Oily Rags are generated during cleaning of different types of tanks and spaces of vessels during the entire ship recycling process. The sand used for cleaning oily tanks is resultantly contaminated with oil contents which makes it hazardous in nature. Oily rags used for cleaning cannot be reused in any way. The oily sand and rags are collected in bags and disposed to TSDF/GGEPIL site with special signage being used on bags containing oily sand and rags.

- Bilge Water is normally removed by pumping out facility at ports but some bilge water remains on the vessel during beaching and is required to be pumped out by yard resources and sent to TSDF /GGEPIL located in Alang. Bilge water records are maintained onboard the vessel being recycled. Special signage is used for tanks containing bilge water in the yard.

- Many usable batteries are recovered from the vessels being recycled and are reused in the yard utility equipments such as cranes and winches. Batteries which are found unusable are collected and sent for disposal to TSDF / GGEPIL site.

- Rubber and plastic items are collected in the non-hazardous storage area of the yard. Both materials are collected in bags with special signage for identification and are disposed to TSDF / GGEPIL in Alang on periodic basis.

- Glass wool is used in insulation onboard vessels like asbestos and normally is white or yellow in colour. The glass wool is collected in bags with special signage for identification and is disposed to TSDF / GGEPIL in Alang on periodic basis.

- Cement and ceramic waste are collected in non-hazardous waste storage rooms in the yard in bags and then sent to TSDF site / GGEPIL on periodic basis.

From Challenges to Opportunities

In specific reference to ship recycling and India’s evolving maritime practices, Gujarat Chief Minister, Shri Bhupendra Patel, made a significant announcement at an International Seminar on Ship Recycling and Vehicle Scrap Policy in September 2022 at Gandhinagar. Drawing attention to Gujarat’s extensive coastline and maritime heritage, he underscored the state’s pivotal role in India’s port-led development. The Chief Minister specifically addressed the burgeoning field of ship recycling, accentuating a transition towards green practices. He stated that this transformation aligns with the vision set forth by the government of India through the enactment of the Recycling of Ships Act, 2019 and reiterated Gujarat’s aspiration to position Alang as a leading green ship recycling hub, showcasing India’s commitment to environmentally friendly practices while invigorating the ship recycling industry. The event served as a testament to Gujarat’s integral role in India’s economic development, shedding light on advancements in the ship recycling and broader maritime sector.[44]

Continuing the narrative on India’s ambitious plans for the ship recycling industry, the government’s forward-looking document, Maritime Amrit Kaal Vision 2047, extends the trajectory defined by the Maritime India Vision 2030 (MIV 2023). The 2047 vision outlines a timeline and the collaborative efforts required from various stakeholders to address the major challenges confronting the Indian Ship Recycling Industry. The focused efforts outlined in Maritime Amrit Kaal Vision 2047 and enumerated in the table below represents a proactive approach to transform challenges into opportunities and position India as a global hub for environmentally sustainable ship recycling practices.

| Sl No. | Issues/

Challenges |

Present status | Proposed consideration | Action Plan for implementation | Timeline |

| 1 | Underutilization of the available infrastructure, of the 153 plots in Alang, 131 have been allotted and 22 are vacant.

Approximately 48 percent under-utilization of working plots handling average 2 MMTPA of LDT. |

Resize the plots in ASSRY and create an extra recycling cluster on the East Coast of India to bolster ship recycling infrastructure under the MIV 2030 initiative. | Enhancement of existing utilized

capacity of 2 Million Metric Tonnes Per Annum (MMTPA) (131 plots) at ASSRY to 5.24 MMTPA |

· Relaxation in Annual fixed Charges

· Amendment in Constitution changes of plot holder · Transfer of Plots |

Q4, 2023 |

| Adding 22 plots to enhance capacity to 0.88 MMTPA

· Auction of 8 plots as directed by the Honourable Supreme Court of India · Amendments in Reservation Policy in a non-arbitrary manner, as directed by the Honourable Supreme Court of India Auction of 14 plots |

Q3, 2025 | ||||

| Adding 15 plots to enhance capacity to 1.20 MMTPA

Coastal Regulatory Zone (CRZ) Clearance, Land Acquisition and Extension of road. Adding 30 plots to enhance capacity to 2.40 MMTPA CRZ Clearance, Land Acquisition and Project Management Consultant (PMC) Finalization |

Q3, 2025 | ||||

| 2 | Higher Taxes | Import Duty 2.5% and GST 18% being levied. | Reduction in tax rate in line with imported baled scrap | Detailed study to arrive at revised tax rates | Q4, 2023 |

| Ministry of Ports, Shipping and Waterways (MoPSW) to send representation to Income Tax department | Q4, 2023 | ||||

| Approval from Income Tax department | Q1, 2024 | ||||

| 3 | Overcoming the BIS Non-Recognition Barrier: Exploring Solutions for the Integration of Recycled Steel in Diverse Sectors, with a Focus on the Real Estate Industry | BIS not recognizing recycled

Steel. Projects already identified under the initiative: – (Source: MIV 2030) Modification of BIS regulations (IS 1786:2008) governing TMT bar production to allow usage of ship scrap basis material composition and strength/ quality in place of existing requirement of metallurgical history |

Amend BIS Regulation (IS 1768:2008) for Thermo Mechanically Treated steel (TMT) bar production to permit the use of ship scrap, focusing on material composition, strength, and quality, as an alternative to the current metallurgical history requirement | Proposal to Bureau of Indian Standards (BIS) based on detailed study | Q4, 2023 |

| Approval from BIS | Q4, 2023 | ||||

| 4 | Limited Ship Recycling Clusters | Development of other ship recycling clusters | Development of other ship recycling clusters at West Bengal and Visakhapatnam | Conduct a comprehensive location study encompassing strategy, business model, finance, taxation, commerce, industry, policy law, foreign trade, etc., to finalize destinations | Q4, 2023 |

| Prepare and submit a proposal to the MoPSW with the rationale, tentative budget, and suggested action for approval | Q4, 2023 | ||||

| Land acquisition and CRZ clearance | Q4, 2024 | ||||

| Issue Request for Proposal (RFP) for development of ship recycling clusters with suitable business

Model |

Q1, 2025 | ||||

| Development of facility | Q4, 2026 | ||||

| 5 | Limited Marketability of ship by-products and lack of transparency | Collaborate with other countries through MEA to establish a ship recycling facilitation centre, promoting recycling activities and enhancing marketability of ship by-products via trade fairs at ship breaking yards, involving stakeholders from shipowners to downstream industries, as identified under the MIV 2030 initiative | Intervention of MEA, Government of India

with European Union, OECD countries for sending their vessels directly to ASSRY without routing through Flag of Convenience (FOC) with subsidized selling price like Turkey. MEA may also intervene with EU countries to send their vessels to Alang at subsidized rates considering HKC compliance status |

Detailed study to arrive at subsidised rates in line with international bodies | Q4, 2023 |

| Proposal to Ministry of External Affairs (MEA) to collaborate with countries to send their vessels directly to

Alang without routing through FOC with subsidized selling price |

Q4, 2023 | ||||

| Approval from MEA | Q2, 2024 |

Table 4. Action Plan of Indian Government for Ship Recycling Sector

Source: Maritime Amrit Kaal Vision 2047, Maritime India Vision 2030 and through interactions of Authors with stakeholders[45] [46]

Recommendations

The ship recycling industry in Alang has witnessed positive changes in recent years, yet challenges persist, especially in environmental and safety aspects. To foster further improvement and sustainability, the following recommendations are proposed:

Promotion of India’s Ship Recycling Sector:

- Organize annual seminars to promote sustainable ship recycling, emphasizing benefits and solutions.

- Improve transparency to enhance the industry’s global image and showcase Alang’s development.

Inspection and Worker Rights:

- Increase administrative and financial capacity for regular inspections.[47]

- Establish a comprehensive database on migrant workers with regular updates.[48]

- Provide detailed education on workers’ rights under labour laws.

Environmental Monitoring and Transparency:

- Develop a transparent environmental monitoring system.

- Conduct a GAP analysis to identify areas for improvement in medical facilities and waste management.

Enhanced Drainage System and Cutting Methods:

- Address the effectiveness of the drainage system in the secondary cutting zone.

- Examine alternative cutting methods, especially water jet cutting to minimize risks.[49]

Sustainable Coat-Stripping Techniques:

- Explore sustainable coat-stripping methods, such as dry ice blasting, to reduce emissions of hazardous pollutants.[50]

- Investigate the transition from traditional sand blasting to environmentally friendly alternatives.

Circular Economy Transition:[51]

- Work towards transitioning ship recycling into a circular economy.

- Implement circular economy policies for improved scrap steel availability.

- Utilize optical recognition and artificial intelligence for precise scrap quality assessment.

These recommendations encompass short-, medium-, and long-term strategies aimed at addressing immediate concerns while fostering the long-term sustainability of Alang’s ship recycling industry. The implementation of these measures will contribute to enhancing environmental practices, worker safety, and the overall reputation of Alang on the global stage.

Conclusion

India’s ship recycling industry, centred around the ASSRY, stands at a critical juncture where challenges and opportunities intersect. The historical shift of ship recycling activities from the Global North to South Asia, driven by stringent regulations, has positioned India as a key player in the sustainable disposal of End-of-Life vessels.[52] The economic and environmental advantages of responsible ship recycling, exemplified by the ASSRY, highlight the potential for India to become a global leader in this sector.

The challenges faced by the Indian ship recycling sector, including underutilization of plots, high compliance costs, tax burdens, demand a comprehensive approach for policy reforms and strategic planning. The significant strides made in Alang, especially in addressing concerns related to worker safety, environmental pollution, and regulatory compliance, reflect a positive trajectory. Recent developments, such as the commitment to green practices and the vision outlined in Maritime Amrit Kaal Vision 2047, further reinforce India’s commitment to sustainable ship recycling practices.

The recommendations put forth, ranging from promoting India’s ship recycling sector and capacity building to addressing environmental concerns and adopting circular economy principles, provide a roadmap for the industry’s sustained growth. These recommendations, if implemented diligently, can contribute to enhancing Alang’s global standing, ensuring responsible ship recycling practices, and aligning with India’s aspirations for a green and economically robust maritime sector. The evolution of Alang from facing challenges to embracing opportunities symbolizes a commitment to environmental stewardship and responsible industry practices, setting the stage for India to become a beacon of environmental sustainability in the ship recycling landscape.

******

About the Authors

Ayushi Srivastava is a Research Associate at the National Maritime Foundation (NMF). She holds a BTech degree from the APJ Abdul Kalam Technical University, UP, and an MTech degree in naval architecture and ocean engineering from the Indian Maritime University (IMU), Visakhapatnam Campus. Her current area of research focus is shipping and shipping-technologies, particularly those aspects that support India’s ongoing endeavour to transition from a ‘brown’ model of economic development to a ‘blue’ one. She can be reached at ps1.nmf@gmail.com.

Commodore Debesh Lahiri is a serving officer of the Indian Navy and is presently, the Executive Director of the National Maritime Foundation (NMF) New Delhi. He is a regular speaker at webinars/seminars/workshops and conferences in India and abroad. He has authored/co-authored book chapters/technical project reports/well-researched articles and was a member of the Expert Advisory Group on Blue Economy to the Ministry of Environment, Forests and Climate Change (MoEF and CC) during India’s presidency of the G20. His areas of research-interest include maritime geo-strategies of Russia, Israel, UK, US, and multilateral/regional constructs, Blue Economy and Climate Change, Disaster Resilience, Marine Pollution, Illegal Unreported and Unregulated (IUU) Fishing, Shipbuilding, Ship Repair and Ship Recycling, Multi-disciplinary technical subjects etc. He can be reached at debeshlahiri@gmail.com or execdir.nmf@gmail.com.

Endnotes:

[1] R. Scott Frey, “Breaking Ships in the World-System: An Analysis of Two Ship Breaking Capitals, Alang India and Chittagong, Bangladesh”, Tennessee Research and Creative Exchange (TRACE), University of Tennessee, Knoxville, May 2013.

https://trace.tennessee.edu/cgi/viewcontent.cgi?article=1001&context=utk_cssjpapers

[2] Md. Golam Mohiuddin et, “Analysis of Present Global Ship Recycling Status and Challenges for Bangladesh”, Global Scientific Journals Volume 11, Issue 4, April 2023

[3] Ibid

[4] Disposal of Vessels at Sea, United States Environmental Protection Agency, accessed on 24 November 2023

https://www.epa.gov/ocean-dumping/disposal-vessels-sea

[5] Soumyajit Dasgupta, “10 Types of Ship Disposal Techniques”, Marine Insight, 02 April 2019

https://www.marineinsight.com/guidelines/10-types-of-ship-disposal-techniques/

[6] Disposal of Vessels at Sea, United States Environmental Protection Agency, accessed on 24 November 2023

https://www.epa.gov/ocean-dumping/disposal-vessels-sea

[7] Ibid

[8] Ananya Mukherjee and Bhavna Shri Harsha, “Maritime Pollution and the Shipbreaking Industry — Challenges and Mitigation-Options”, National Maritime Foundation, 05 April 2021

[9] Ibid

[10] The Problem, NGO Shipbreaking Platform, accessed on 24 November 2023

https://shipbreakingplatform.org/our-work/the-problem/

[11] Md. Golam Mohiuddin et al., “Analysis of Present Global Ship Recycling Status and Challenges for Bangladesh”, Global Scientific Journals Volume 11, Issue 4, April 2023

[12] Ibid

[13] Ibid

[14] Recycling of ships, International Maritime Organisation (IMO), accessed on 08 December 2023

https://www.imo.org/en/ourwork/environment/pages/ship-recycling.aspx

[15] The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, International Maritime Organisation (IMO), accessed on 08 December 2023

[16] Maritime Amrit Kaal Vision 2047, Ministry of Ports, Shipping and Waterways (MoPSW), Government of India, October 2023

[17] Annual Report 2022-23, Ministry of Ports, Shipping and Waterways (MoPSW), Government of India, 2022-23

https://shipmin.gov.in/sites/default/files/Annual%20Report%202022-23%20English.pdf

[18] Maritime Amrit Kaal Vision 2047, October 2023, Pg. 218

[19] Ibid

[20] Ibid

[21] Google Earth, accessed on 14 December 2023

[22] Annual Report 2022-23, Pg. 50

[23] Maritime Amrit Kaal Vision 2047, October 2023, Pg. 218

[24] Annual Report 2022-23, Pg. 50

[25] Environmental Impact Assessment and Environmental Management Plan, Proposed Upgradation of Existing Ship Recycling Yard at Alang Sosiya, Gujarat for Undertaking Safe and Environmentally Sound Ship Recycling Operations, Gujarat Maritime Board and Mecon Limited, July 2016

[26] Presentation on Alang Ship Breaking Yard, Gujarat Maritime Board (GMB), Government of Gujarat, accessed on 14 December 2023

https://www.imaritime.com/knowledgebase/test1.pdf

[27] “Alang-Sosiya: The world’s biggest ship recycling yard gears up for eco-friendly recycling”, YouTube video, 9:05, “CMO Gujarat”, September 2022, https://www.youtube.com/watch?v=0ZZHw-N42c4&t=1s

[28] “Net zero emission target”, Press Release, Ministry of Environment, Forest and Climate Change, Government of India, August 2023

https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1945472

[29] Ibid

[30] Ms Rhythma Kaul and Commodore Debesh Lahiri “Sustainable Ship Recycling in India- Legal, Economic and Political Analysis”, National Maritime Foundation, January 2024

[31] Maritime Amrit Kaal Vision 2047, October 2023, Pg. 218

[32] Hrudanand Misra, “Analysis of Alang Ship Breaking Yard, India”, Institute of Management, Nirma University, Ahmedabad, Gujarat, India, Economic Affairs, Vol. 64, No. 2, pg. 417-424, June 2019

[33] Ibid

[34] Environmental Impact Assessment and Environmental Management Plan, Pg. ES-1

[35] Environmental Impact Assessment and Environmental Management Plan, Pg. ES-1

[36] Ms Rhythma Kaul and Commodore Debesh Lahiri, “Sustainable Ship Recycling in India- Legal, Economic and Political Analysis”, National Maritime Foundation, January 2024

https://maritimeindia.org/sustainable-ship-recycling-in-india-legal-economic-and-political-analysis/

[37] Shipbreaking Code (Revised) 2013, Government of India

https://shipmin.gov.in/sites/default/files/1157392371CBCODErevised201310022017_0.pdf

[38] “Green Ship Recycling Facility”, Arya Steel Handbook

[39] Ingvild Jenssen, Nicola Mulinaris, Sara Costa, Benedetta Mantoan, Pilar Gianni Rodríguez, “Impact Report 2020-21”, NGO Ship Breaking Platform Rue de la Linière 11, B – 1060 Brussels

https://shipbreakingplatform.org/wp-content/uploads/2022/11/NGO-SBP-Annual-Report-2020_2021.pdf

[40] Preparatory Survey on the Ship Recycling Yard Improvement Project in India, Final Report (Draft), Japan Marine Science Inc., Padeco Co. Ltd and Japan Development Institute Co. Ltd., Japan International Cooperation Agency, July 2017

[41] Environmental Impact Assessment and Environmental Management Plan, July 2016

[42] Ibid

[43] Ibid

[44] Gujarat has full potential to become a green ship recycling hub: Chief Minister, CMO Gujarat, 12 September 2022

[45] Maritime Amrit Kaal Vision 2047, October 2023, Pg. 429 – 433

[46] Maritime India Vision 2030, Ministry of Ports, Shipping and Waterways (MoPSW), Government of India, February 2021, Pg. 163-165

[47] Geetanjoy Sahu, “Working, Living, Occupational Health and Safety Conditions of Workers in Ship Breaking Yards in Alang-Sosiya, Gujarat, India”, Tata Institute of Social Sciences (TISS), Mumbai, 2019

[48] Ibid

[49] “Breaking Out: Anchoring Circular Innovation for Ship Recycling”, NGO Shipbreaking Platform, 20 September 2022

https://shipbreakingplatform.org/wp-content/uploads/2022/10/Breaking-Out-Magazine.pdf

[50] Ibid

[51] Ibid

[52]Anand M Hiremath et al, “Significant steps in ship recycling vis-a-vis wastes generated in a cluster of yards in Alang: a case study”, Journal of Cleaner Production, Volume 87, January 2015

https://www.sciencedirect.com/science/article/abs/pii/S0959652614009615

Leave a Reply

Want to join the discussion?Feel free to contribute!